SPS Start to Finish

What We Do

Manufacturing

Various components from mild steel and stainless steel

Services

All services are backed by extensive field service and maintenance teams

Mill Relining

More than liner replacements

Spare Parts

We provide various levels of refurbishment or repairs to components

Our Vision is to Be our Customer’s Most Trusted Partner – from “Start to Finish”

About Us

SPS South Africa, based near Brits in the North West Province, and SPS Mozambique, based in Matola 80km from the South African border, were established to provide solutions to the mining, minerals processing and metals processing industries in Africa.

SPS has been supporting mining giants throughout Africa with our extensive application knowledge, technical expertise and practical service capabilities to provide customer-specific solutions.

Our logo, “Start to Finish”, is the testimony of our ability to support you with any challenge, up to the final implementation of a value-adding solution. We design, manufacture, deliver, install, maintain and supply spares on time, every time.

SPS caters for the diverse requirements of most industrial applications, with an emphasis on maintaining close relationships with our customers to develop true partnerships. We partner with you for the entire life of your operation, by providing equipment refinement and focuses on optimising the efficiency of your operations to lower your overall cost of business.

We deliver world-class services by maintaining our ISO certification. SPS is currently certified with ISO 9001-2015; ISO 14001-2015; ISO 45001-2018 and ISO 3834-2.

Our Directors

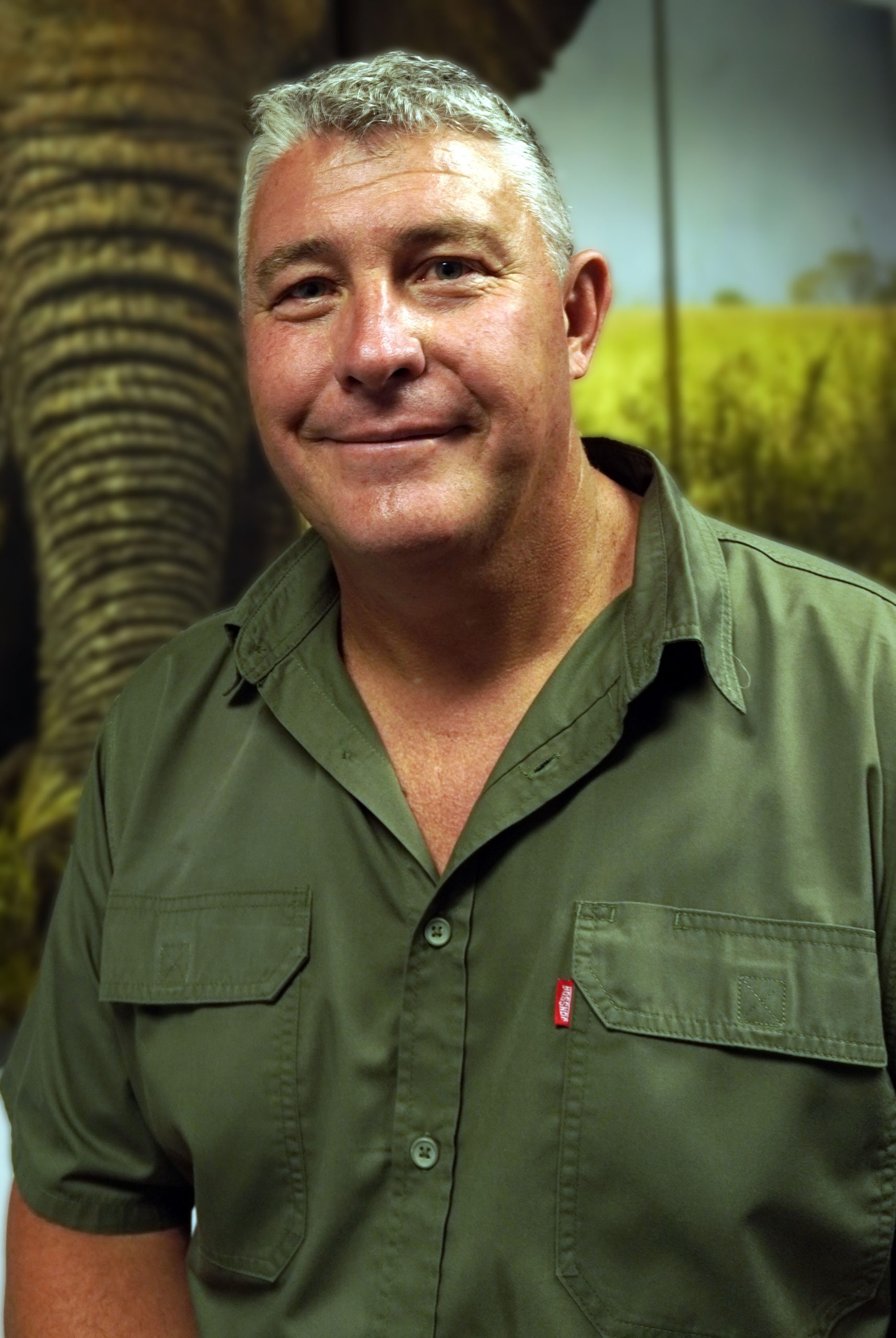

Biography: Desmond Keeling

(Shareholder & Managing Director)

Desmond has a qualification in mechanical engineering and is a qualified technical tradesman. His hands-on experience as a tradesman, combined with his tertiary qualification in mechanical engineering and his natural talent in engineering solutions, makes Desmond the ideal candidate to make sure SPS delivers innovative solutions to our customers.

In his career of more than 30 years, Desmond held various positions in an engineering and fabricating environment.

Desmond was a founding member of SPS in 2010.

Biography: Dumi Nxumalo

(Shareholder & Logistics/Warehousing)

Dumi has a qualification in Purchasing and Supply Management. Dumi joined SPS in 2011 and proved his worth as an employee, manager and now as a Director of SPS. In his career of more than 20 years, Dumi held various positions in the logistics and supply chain management. Dumi has an excellent understanding of the business of SPS and the customer needs, specifically around structuring of resources to satisfy the customer demands during unplanned shutdowns. Dumi’s contribution to SPS resulted in him being appointed as a Director in 2020.

Biography: Dirk Slabbert

(Shareholder & Business Development)

Dirk has an engineering degree in metallurgy and was a registered professional engineer with the Engineering Council of South Africa for several years.

In his career of more than 30 years, Dirk held various positions from process engineering, technical sales, business development and management of the Sub-Saharan African portfolio for a large multi-national company.

Dirk’s focus is on customer centricity and utilising the most important aspect of life and business, people, to drive stimulating growth for employees, value for customers and business growth for all stakeholders involved in SPS.

Recent Projects

SHEQ

SPS Quality, Environmental and Health & Safety is based on business objectives and requirements, internal policies, safety rules, legal requirements and International Standards.

We operate and function in accordance with South African legislation, ISO 9001, 14001, 45001 and International Standards, ISO 3834-2 and Industry Best Practice.

SPS is committed to the Quality, Environment and Health and Safety compliance ethos and is managed as part of an Integrated Management System which is confirmed and validated by Internal audits.

Technical Capabilities

We provide technical support, from aiding with appropriate equipment selection through to delivery accuracy. We also do hot and cold commissioning. In addition, comprehensive plant, process and equipment audits can be carried out on request and we offer a retrofitting equipment service.

With regards to retrofitting, our available resources ensure a seamless operation. All retrofitted equipment can extract maximum value from your mineral processing application.